Basic Info.

Model NO.

1/4"-2"

Length

10-100meter Per PCS

Features

Flexible, Anti-UV, Anti-Oil

Temperature

-5ºC+ to 100ºC

Working Pressure

80-350bar

Burst Pressure

320-1400bar

Delivery Time

Within 20days

Transport Package

PVC Seaworhty Film/ Woven Belts

Specification

1/4"-3"

Trademark

ABLEFLEX or OEM

Origin

China

HS Code

40092100

Production Capacity

3-8ton/Day

Product Description

One and Two Wire Braid R1 R2 1SN 2SN Excavator Hydraulic Rubber Hose

More size is available, pls contact us for more information.

A: Generally, we pack our goods in plastic bags for inner package.Out package you could choose the carton box or woven bags.

Q2. What is your terms of payment?

A: T/T ,30% In Advanced, and 70% Before delivery,Or L/C. The pictures of products detials and packages will be sent before you pay the balance.

Q3. What is your terms of delivery?

A: FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take within 10 to 30 days as receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.But the delivery charges will be deducted from the customer's future order.

Q6. Do you test all your goods before delivery?

A: Yes,we have three inspection steps to make sure the products you received in high quality.

Q7: Are you accept the OEM?

A: Yes,we support the OEM or ODM.

Q8: Our port of shipment?

A: Qingdao,China or as your request.

| SAE 100R1 AT / DIN20022 EN 853 1SN |

| Construction: Tube: Oil resistant synthetic rubber Reinforcement: One high tensile steel wire braid Cover: Oil and weather resistant synthetic rubber Temperature: -40°C to +100°C Application: Petroleum based hydraulic fluid, water, diesel fuels, lubricating oils, glycol, mineral oils, and more. |

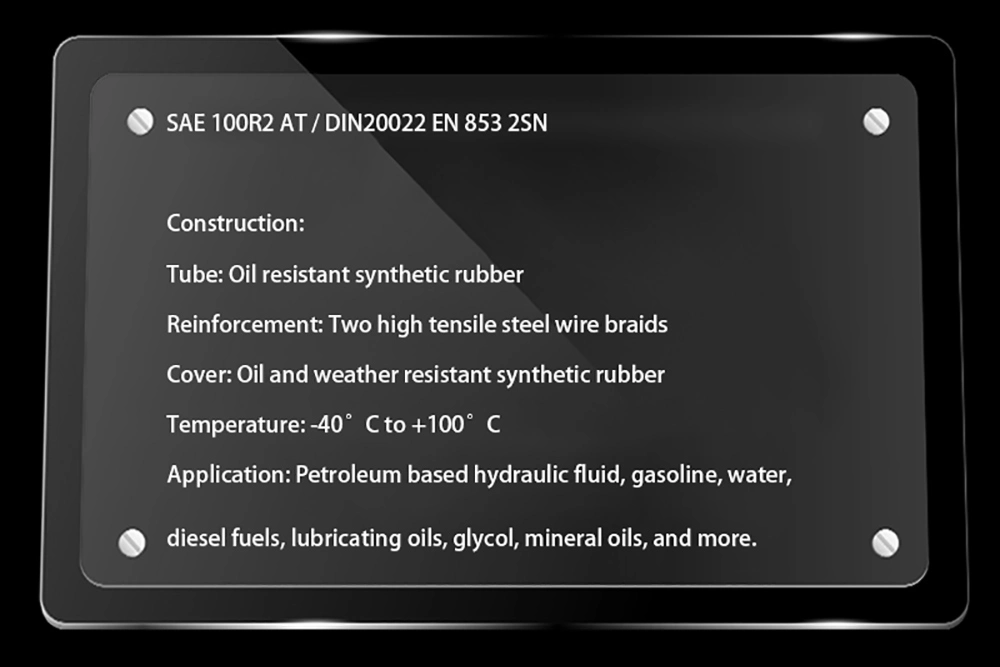

| SAE 100R2 AT / DIN20022 EN 853 2SN |

| Construction: Tube: Oil resistant synthetic rubber Reinforcement: Two high tensile steel wire braids Cover: Oil and weather resistant synthetic rubber Temperature: -40°C to +100°C Application: Petroleum based hydraulic fluid, water, diesel fuels, lubricating oils, glycol, mineral oils, and more. |

| Hydraulic Hose | Reinforcement | Product Name |

| One steel wire braided | SAE R1AT/DIN 1SN,SAE R1AT/DIN 1ST,DIN 1SNK,DIN/EN 1SN WG,DIN 1SC,SAE R5,SAE 100R17 | |

| Two steel wire braided | SAE R2AT/DIN 2SN,SAE R2AT/DIN 2ST,DIN 2SNK,DIN 2SC | |

| One/two wire braided | SAE R16 | |

| Four steel wire spiral | SAE R9AT,SAE R10,SAE R12,DIN 4SP,DIN 4SH | |

| Four/six wire spiral | SAE R13,SAE R15 | |

| Textile fiber braided | SAE R3,SAE R6 | |

| High tensile strength Cord+steel wire spiral | SAE R4 |

| Item Code | Size | Inside | Braid | Outside | Working Pressure | Burst Pressure | Bend Radius | Weight | ||||

| Ø mm | Ø mm | Ø mm | ||||||||||

| Inch | mm | Min | Max | Min | Max | Max | Bar | Psi | Bar | mm | Kg/m | |

| R1-05 | 3/16" | 5 | 4.6 | 5.4 | 8.9 | 10.1 | 12.5 | 250 | 3625 | 1000 | 90 | 0.19 |

| R1-06 | 1/4" | 6.3 | 6.2 | 7.0 | 10.6 | 11.7 | 14.1 | 225 | 3260 | 900 | 100 | 0.21 |

| R1-08 | 5/16" | 8 | 7.7 | 8.5 | 12.1 | 13.3 | 15.7 | 215 | 3120 | 850 | 115 | 0.24 |

| R1-10 | 3/8" | 10 | 9.3 | 10.1 | 14.5 | 15.7 | 18.1 | 180 | 2610 | 720 | 130 | 0.33 |

| R1-13 | 1/2" | 12.5 | 12.3 | 13.5 | 17.5 | 19.0 | 21.5 | 160 | 2320 | 640 | 180 | 0.41 |

| R1-16 | 5/8" | 16 | 15.5 | 16.7 | 20.6 | 22.2 | 24.7 | 130 | 1885 | 520 | 200 | 0.45 |

| R1-19 | 3/4" | 19 | 18.6 | 19.8 | 24.6 | 26.2 | 28.6 | 105 | 1520 | 420 | 240 | 0.58 |

| R1-25 | 1" | 25 | 25.0 | 26.4 | 32.5 | 34.1 | 36.6 | 88 | 1280 | 350 | 300 | 0.88 |

| R1-21 | 1 1/4" | 31.5 | 31.4 | 33.0 | 39.3 | 41.7 | 44.8 | 63 | 910 | 250 | 420 | 1.23 |

| R1-38 | 1 1/2" | 38 | 37.7 | 39.3 | 45.6 | 48.0 | 52 | 50 | 725 | 200 | 500 | 1.51 |

| R1-51 | 2" | 51 | 50.4 | 52.0 | 58.7 | 61.7 | 65.9 | 40 | 580 | 160 | 630 | 1.9 |

| Item Code | Size | Inside | Braid | Outside | Working Pressure | Burst Pressure | Bend Radius | Weight | ||||

| Ø mm | Ø mm | Ø mm | ||||||||||

| Inch | mm | Min | Max | Min | Max | Max | Bar | Psi | Bar | mm | Kg/m | |

| R1-05 | 3/16" | 5 | 4.6 | 5.4 | 9.0 | 10.0 | 12.5 | 250 | 3625 | 1000 | 90 | 0.19 |

| R1-06 | 1/4" | 6.3 | 6.2 | 7.0 | 10.6 | 11.1 | 14.1 | 225 | 3260 | 900 | 100 | 0.21 |

| R1-08 | 5/16" | 8 | 7.7 | 8.5 | 12.1 | 12.7 | 15.7 | 215 | 3120 | 850 | 115 | 0.24 |

| R1-10 | 3/8" | 10 | 9.3 | 10.1 | 14.5 | 15.1 | 18.1 | 180 | 2610 | 720 | 130 | 0.33 |

| R1-13 | 1/2" | 12.5 | 12.3 | 13.5 | 17.5 | 18.3 | 21.4 | 160 | 2320 | 640 | 180 | 0.41 |

| R1-16 | 5/8" | 16 | 15.5 | 16.7 | 20.6 | 21.4 | 24.5 | 130 | 1885 | 520 | 200 | 0.45 |

| R1-19 | 3/4" | 19 | 18.6 | 19.8 | 24.6 | 25.4 | 28.5 | 105 | 1520 | 420 | 240 | 0.58 |

| R1-25 | 1" | 25 | 25.0 | 26.4 | 32.5 | 33.3 | 36.6 | 88 | 1280 | 350 | 300 | 0.88 |

| R1-21 | 1 1/4" | 31.5 | 31.4 | 33.0 | 39.3 | 40.5 | 44.8 | 63 | 910 | 250 | 420 | 1.23 |

| R1-38 | 1 1/2" | 38 | 37.7 | 39.3 | 45.6 | 46.8 | 52.1 | 50 | 725 | 200 | 500 | 1.51 |

| R1-51 | 2" | 51 | 50.4 | 52.0 | 58.7 | 60.2 | 65.5 | 40 | 580 | 160 | 630 | 1.9 |

| Item Code | Size | ID mm | OD mm | WP | BP | B.R | Weight | ||||

| mm | Inch | Min | Max | Max | Mpa | PSI | Mpa | mm | Kg/m | ||

| R2-05 | 5 | 3/16" | 4.6 | 5.4 | 14.1 | 35 | 5250 | 140 | 90 | 0.32 | |

| R2-06 | 6.3 | 1/4" | 6.2 | 7.0 | 15.7 | 35 | 5250 | 140 | 100 | 0.36 | |

| R2-08 | 8 | 5/16" | 7.7 | 8.5 | 17.3 | 29.7 | 4455 | 119 | 115 | 0.45 | |

| R2-10 | 10 | 3/8" | 9.3 | 10.1 | 19.7 | 28 | 4200 | 112 | 125 | 0.54 | |

| R2-12 | 12.5 | 1/2" | 12.3 | 13.5 | 23.1 | 24.5 | 3675 | 98 | 180 | 0.68 | |

| R2-16 | 16 | 5/8" | 15.5 | 16.7 | 26.3 | 19.2 | 2880 | 77 | 205 | 0.8 | |

| R2-19 | 19 | 3/4" | 18.6 | 19.8 | 30.2 | 15.7 | 2355 | 63 | 240 | 0.94 | |

| R2-25 | 25 | 1" | 25.0 | 26.4 | 38.9 | 14 | 2100 | 56 | 300 | 1.35 | |

| R2-32 | 31.8 | 1-1/4" | 31.4 | 33.0 | 49.6 | 11.3 | 1695 | 45.5 | 420 | 2.15 | |

| R2-38 | 38 | 1-1/2" | 37.7 | 39.3 | 56.0 | 8.7 | 1305 | 43.5 | 500 | 2.65 | |

| R2-51 | 51 | 2" | 31.4 | 52.0 | 68.6 | 7.8 | 1170 | 31.5 | 630 | 3.42 | |

| Item Code | Size | ID mm | OD mm | WP | BP | B.R | Weight | ||||

| mm | Inch | Min | Max | Max | Mpa | PSI | Mpa | mm | Kg/m | ||

| 2SN-05 | 5 | 3/16" | 4.6 | 5.4 | 14.1 | 41.5 | 6225 | 165 | 90 | 0.32 | |

| 2SN-06 | 6.3 | 1/4" | 6.2 | 7.0 | 15.7 | 40 | 6000 | 160 | 100 | 0.36 | |

| 2SN-08 | 8 | 5/16" | 7.7 | 8.5 | 17.3 | 35 | 5250 | 140 | 115 | 0.45 | |

| 2SN-10 | 10 | 3/8" | 9.3 | 10.1 | 19.7 | 33 | 4950 | 132 | 125 | 0.54 | |

| 2SN-12 | 12.5 | 1/2" | 12.3 | 13.5 | 23.1 | 27.5 | 4125 | 110 | 180 | 0.68 | |

| 2SN-16 | 16 | 5/8" | 15.5 | 16.7 | 26.3 | 25 | 3750 | 100 | 205 | 0.8 | |

| 2SN-19 | 19 | 3/4" | 18.6 | 19.8 | 30.2 | 21.5 | 3225 | 85 | 240 | 0.94 | |

| 2SN-25 | 25 | 1" | 25.0 | 26.4 | 38.9 | 16.5 | 2475 | 65 | 300 | 1.35 | |

| 2SN-32 | 31.8 | 1-1/4" | 31.4 | 33.0 | 49.6 | 12.5 | 1875 | 50 | 420 | 2.15 | |

| 2SN-38 | 38 | 1-1/2" | 37.7 | 39.3 | 56.0 | 9 | 1350 | 36 | 500 | 2.65 | |

| 2SN-51 | 51 | 2" | 31.4 | 52.0 | 68.6 | 8 | 1200 | 32 | 630 | 3.42 | |

FAQ

Q1. What is your terms of packing?A: Generally, we pack our goods in plastic bags for inner package.Out package you could choose the carton box or woven bags.

Q2. What is your terms of payment?

A: T/T ,30% In Advanced, and 70% Before delivery,Or L/C. The pictures of products detials and packages will be sent before you pay the balance.

Q3. What is your terms of delivery?

A: FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take within 10 to 30 days as receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.But the delivery charges will be deducted from the customer's future order.

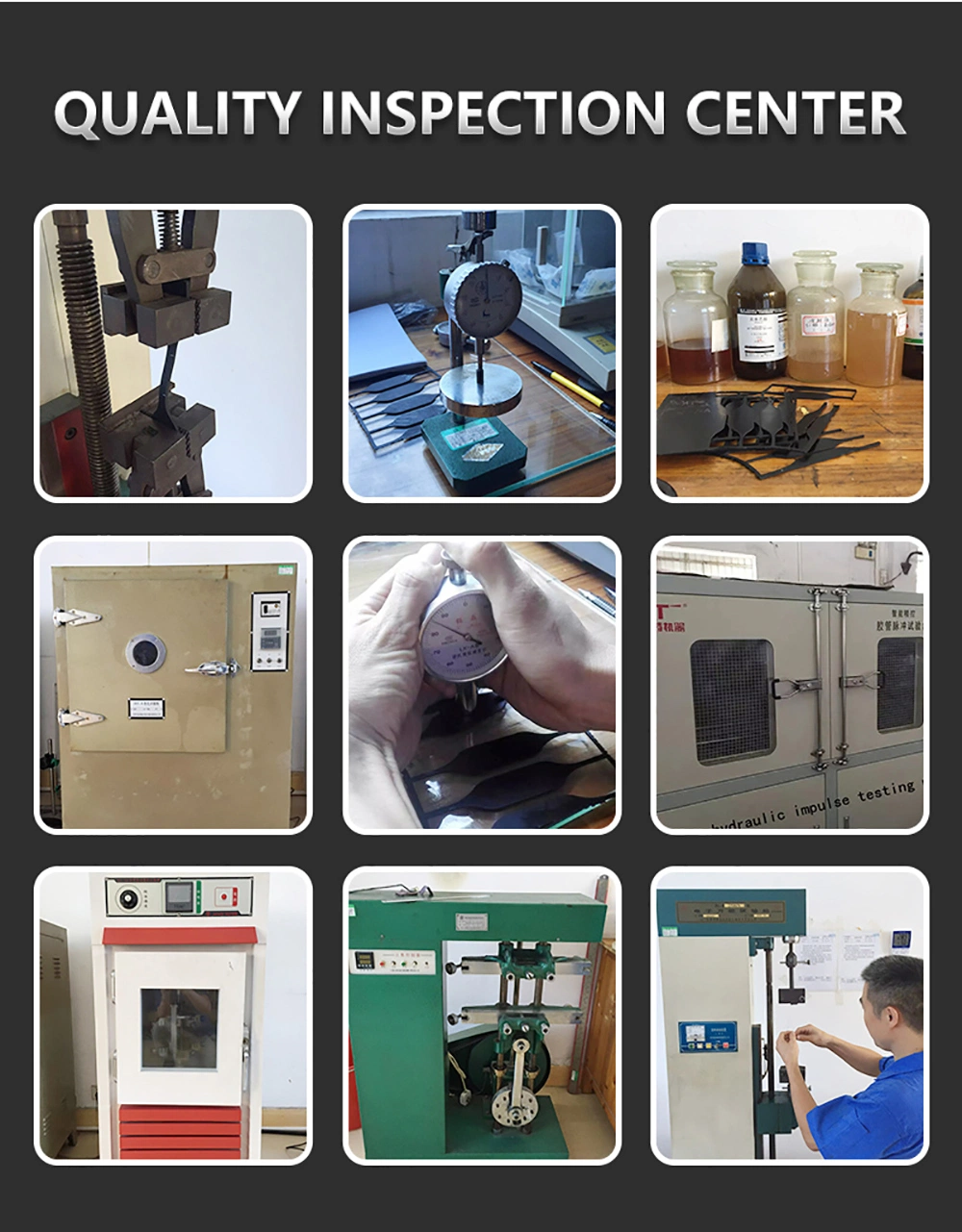

Q6. Do you test all your goods before delivery?

A: Yes,we have three inspection steps to make sure the products you received in high quality.

Q7: Are you accept the OEM?

A: Yes,we support the OEM or ODM.

Q8: Our port of shipment?

A: Qingdao,China or as your request.