- Overview

- Company Information

- Certifications

- Packaging & Shipping

Basic Info.

Packaging & Delivery

Product Description

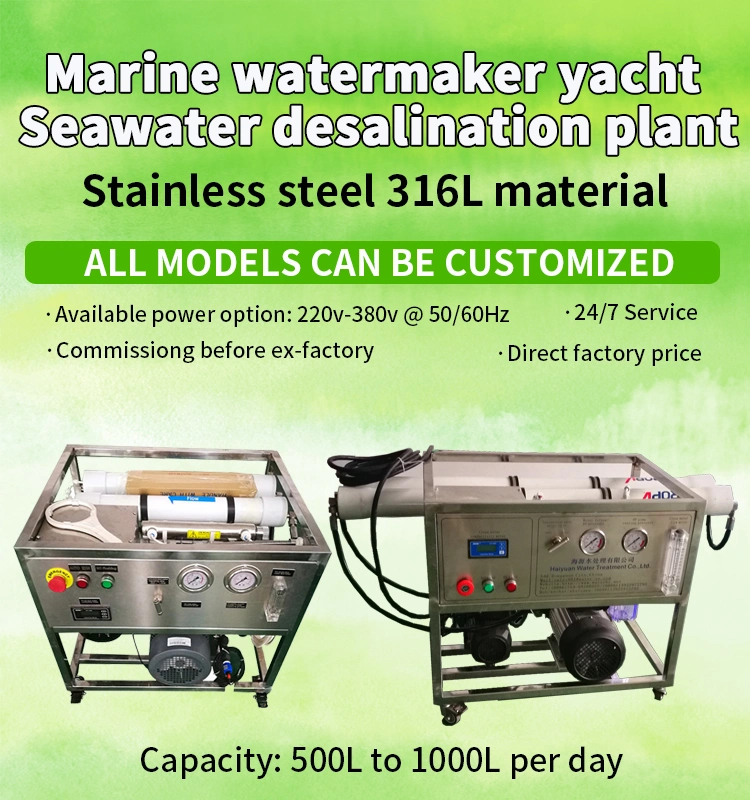

desalinator marine desalinator for sailboat water desalinator for boat

HY have watermaker for boat : 500LPD, 1000LPD, 2000LPD, 3000LPD, 5000LPD, 10000LPD etc....

HY also can do different flow rate according to client's requirements.

It focus on shipping boats.

It is movable and convenient;

Easy operation and less maintenance;

It can turn seawater into direct drinking fresh water;

We also have CE certificate for it.

The Basics of marine water maker for sailboat

Marine water for sailboat use the process of reverse osmosis to intake seawater and output clean, potable water suitable for any of your live-aboard needs. The newly made freshwater is then pumped into your vessel's current water tank, while the leftover "brine" is thrown overboard. Most marine watermakers differ with regards to the method in which the water is pumped. Typically, the water can be either electrically driven (either AC or DC) or powered by your boat's engine. Watermakers also come in all shapes and sizes, with best suited for marine sailboats.

Applications of marine water maker for sailboat

WHO Safe Drinking water;marine water maker for sailboat can be operated at room temperature (5-40), with excellent water production, low energy consumption and low cost.

Can be designed according to the particularity of the ship to achieve small in size, light in weight, small in area, easy to install , convenient installation, strong adaptability.

Can be installed in narrow spaces such as engine room, deck, cabin, aisle, etc

Simple operation and convenient maintenance.

Can increase the total amount of fresh water, and is not affected by time, space and climate.

The water quality is good and the price is gradually reasonable.

Marine water maker for sailboat process

Sea water tank →Feed water pump →Sand filter → Scale inhibition→ 5μSecurity filter →1μSecurity filter → High-pressure pump → RO system (CIP)→ Product water tank

Watermaker for boat fresh water maker for boats feature:

1. Maker for sailboat can plug and play unit,Quick installation.

2. Marine water maker for sailboat made of SS316 frame, beautiful appearance, durable in use.

3. Marine water maker for sailboat to use hose which could reduce vibration and lower noise.

4. Small watermaker for sailboat consist of 5micron fold filter element and 1 micron filter. It will intercept the more than absolutely 5 micron impurities. To avoid them into High pressure pump cause the pump be damaged.

5. Marine water maker for sailboat does not only include the supply of a container, it includes the complete installation of the plant.

6. Marine water maker for sailboat have low and full water level switch in the source tank and fresh water tank.

7. Watermaker for sailboat fresh water maker for boats have Alarm reminding.

8. Online water quality monitor.

9. On/Off/Automatic Mode one key auto flush and start on.

Marine water maker for sailboat generic specifications.

Chlorine Dosing System- disinfection of feed-water

Booster Pump- delivers water at the required flow and pressure 30-40 psig

Multi-Media Filter- Multi-media filtration system is used to filter sand and sediment (turbidity) down to approximately 20 Microns. Both automatic and manual backwash option is available. Corrosion resistant, high performance composite & fiberglass tank will be used to hold the media.

Pre-Filtration System

5 micron cartridge type sediment filter further reduces suspended solids in the feed water stream to RO system.

Sodium Metabisulphite Dosing System

One metering injection systems will be supplied for controlling different elements in the feed water of the RO plant and will neutralise the Chlorine in the feed water.

Acid Dosing System

Acid Dosing will ensure pH is at a level where scaling is reduced. The pH of seawater is normally above 8.

Antiscalant Dosing System

One metering injection systems will be supplied for controlling different elements in the feed water of the RO plant and will reduce membrane fouling.

Caustic Dosing System(Post Treatment)

Caustic Dosing or other pH builders will help to stabilise the treated water and reduce the corrosive nature of RO water.

Chlorine Dosing System(Post Treatment)

The Chlorine Dosing System sterilises product water.

UV Sterilisation System(Post Treatment)

Sterilises product water by alternating the DNA structure inside bacteria.

Ozone System(Post Treatment)

Sterilises product watera

Marine water maker for sailboats product details

| HY-SWRO-100L/hr (2m3/D) | |||

| Flow rate | 2000LPD | Recovery rate | 15% |

| Voltage | 220V,50Hz, 1 phase | Power | 2 KW |

| Feed water TDS | < 40000ppm | Output water TDS | < 600ppm |

| Working pressure | < 1000psi | Working temperature | 5-45ºC |

| Feed water residual chlorine | < 0.1ppm | Feed water SDI | < 5 |

| Feed water turbidity | < 1 | Feed water PH | 3~10 |

| RO membrane housing | 2540 2 piece | RO membrane | 2 piece |

| Specification | 1100*500*500(mm) | Net weigh | About 100Kg |

| Plywood case packing | 1250*600*750(mm) | Gross weight | About 110Kg |

Marine watermakers are usable anywhere from yachts to sailboats. It's important to choose the correct materials of construction to handle seawater (which is highly corrosive).

We have more sizes and output water capacity for your choice:

According to customers' water source analysis report and the final water standard required ,we will suggest customer to choose the suitable water treatment system.

Why we make you choose our maker for sailboat?

1. We can provide oversea service to site installation.

2. OEM&ODM available.

3. The punctual delivery of goods, quality and quantity guaranteed.

4.We have a professional team to provide customers with pre-sales, in-sales and after-sales services.

5.We can provide technical support via phone/email/instant communication tools, or remote video.

6.We have equipment installation/debugging/maintenance, and provide detailed video tutorials (including paper and electronic documents).

7.Portable seawater desalination RO machine packing: Plywood case packing for exporting.

8.We have shipping forwarder to deliver all over the world, customers also can use your own shipping agents.

FAQ:

Q:What's the information you need to know before order?

A1: what's your raw water?

A2: Do you have the water quality test report of the raw water?

A3: what's the capacity per hour of the equipment?

Q:How can I know your machine works well?

A:Before delivery, we shall test the machine working condition for you.

Q.Are you a factory or trading company?

A:Ours is a water treatment machinery and equipment factory with ten years of design experience.

Q: How much will it cost?

A:The price is affected by water quality, process, configurations, etc.Provide the above information to get a quote quickly.

Q: Can you do OEM for me?

A: We accept all OEM orders,just contact us and give me your design.we will offer you a reasonable price and make samples for you ASAP.

Q: When can I get the quotation ?

A: We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation.Please call us or tell us in your mail, so that we could regard your inquiry priority.

We have 2 factories +300 workers+ Qualified engineer+ Overseas service

We are the right supplier. You know why?