Basic Info.

Product Description

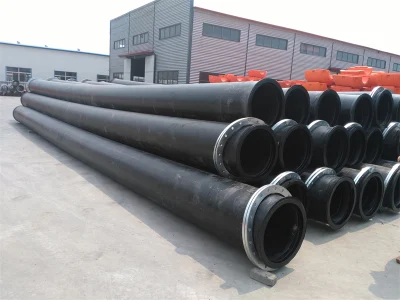

DN400 High Quantity Factory Manufacture HDPE Pipe Floating Hose For Marine Dredging

Place of Origin: Shandong, China (Mainland)

Color: Black or customized

Material: 100% virgin PE 100

Outer Diameter: 710mm

Length: 5.8m or 11.5m to fit shipping containers, certain length also available.

Working Pressure: 0.6MPa~1.5MPa

Wall Thickness: 27.2mm~64.5mm for different working pressure.

Accessories: carbon steel flanges rings, rubber gaskets, bolts-nuts-washers.

Structure and Connection of Dredging Marine HDPE Pipe With Pipe floats DN710

1. Enlarged end, or flare end some people call, No welding required.

2. Nodular cast Iron inserts at end to protect it from deformation,breaking and leakage

3. Loose flang rings (carbon steel, galvanized) at both ends

4. Rubber gasket in between when two pipes are connected by bolts and nuts.

Advantages of Dredging Marine HDPE Pipe With Pipe floats DN710

1. Light weight, easy for transportaion and installation.

2. Good flexibility, tensille force and strength.

3. Strong wear resistance & corrosion resistance

4. Flared ends, no welding, loose flanges at both ends.

5. Smooth inner wall, small friction coefficient.

6. Enviromental friendly.

Some loading & Delivery Pictures

Dredging Marine HDPE Pipe With Pipe floats DN710 from OD32 mm to 1000mm, the sizes are as following:

DN-MM | Standard size | ||||

| SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | |

| Working Pressure - Mpa | |||||

| 0.6 | 0.8 | 1.0 | 1.25 | 1.6 | |

| Nominal wall thickness-mm | |||||

| 32 | 2.0 | 2.4 | 3.0 | ||

| 40 | 1.8 | 2.0 | 2.4 | 3.0 | 3.7 |

| 50 | 2.0 | 2.4 | 3.0 | 3.7 | 4.6 |

| 63 | 2.5 | 3.0 | 3.8 | 4.7 | 5.8 |

| 75 | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 |

| 90 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 |

| 110 | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 |

| 125 | 4.8 | 6.0 | 7.4 | 9.2 | 11.4 |

| 140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 |

| 160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 |

| 180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 |

| 200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 |

| 225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 |

| 250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 |

| 280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 |

| 315 | 12.1 | 15.0 | 18.7 | 23.2 | 28.6 |

| 355 | 13.6 | 16.9 | 21.1 | 20.1 | 32.2 |

| 400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.4 |

| 450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 |

| 500 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 |

| 560 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 |

| 630 | 24.1 | 30.0 | 37.4 | 46.3 | 57.2 |

| 710 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 |

| 800 | 30.6 | 38.1 | 47.4 | 58.8 | |

| 900 | 34.4 | 42.9 | 53.3 | 66.1 | |

| 1000 | 38.2 | 47.7 | 59.3 | ||

Our factory introduction:

Shandong Xincheng Pipe Co., Ltd has been manufacturing plastic Dredging HDPE Pipe since 2008. The pipes are made from high wear resistance PE 100 mixed with anti-UV material by extrusion molding technology. The slurry HDPE pipes enjoy a good market for its solid one-piece structure and perfect quality. Our clients are from worldwide. The enlarged ends are lined with steel rings. It equips with loose flanges at both ends. When two pipes are connected ,there is a rubber gasket in between.

FAQ of Dredging Marine HDPE Pipe With Pipe floats for sand and slurry DN710

Q. Are you a manufacturer, trading company or a third party?

A. We are a manufacturer since 2008, the production site is near XUZHOU Airport and Zaozhuang high-speed railway station, welcome to our factory.

Q. What is your minimum order quantity, can you send me samples?

A. Our minimum quantity is 1 set, and samples are available.

Q. How to choose the working pressure?

A. Generally, 0.8Mpa is enough for a dredging project. But if there are coarse slurry or corals, please let us know, then we will suggest a proper working pressure for you.

Q. How long is the length?

A. Because of the container limitation, we suggest pipe length at 5.8m or 11.5m.

Q. Compared with stub end pipes, what is the advantages of your pipe?

A. Our pipe is well known for its solid one-piece structure, it has better tensile strength.

Q. What if I have a special application?

A. Submit your detailed request to our email, then we will provide you a quick answer.