Basic Info.

Product Description

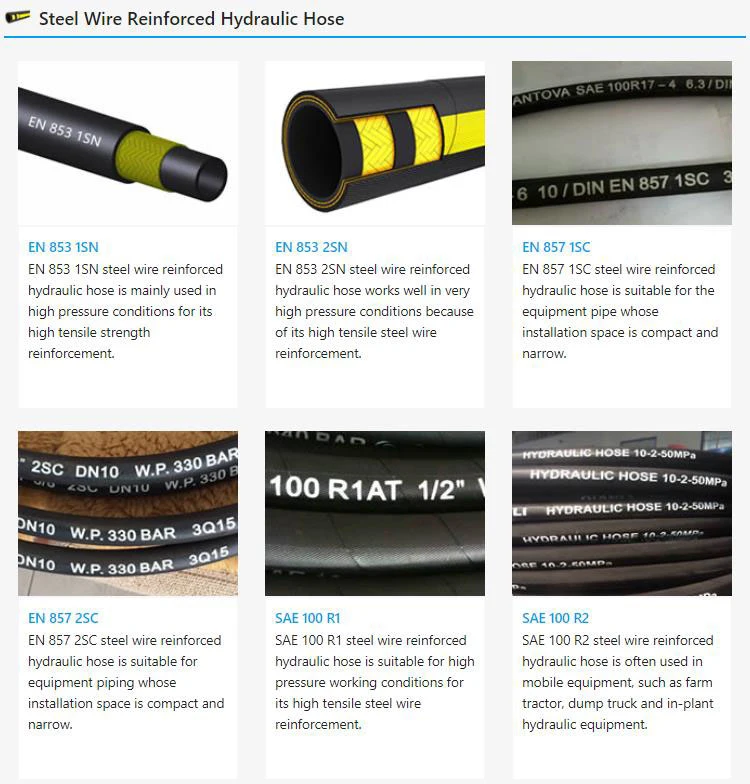

SAE 100 R1 Steel Wire Reinforced Hydraulic Hose with Long Service Life

SAE 100R1AT single steel wire braided hose is a typical medium pressure hydraulic hose and strongly recommended for hydraulic lines or general industrial system. It can bear higher working pressure than other rubber hoses thanks to its high tensile braided steel wire reinforcement. It is composed of three parts: tube, reinforcement and cover. The tube is made from oil resistant synthetic rubber, making the hose have excellent performance in delivering oils. The reinforcement is made from one layer of high tensile braided steel wire, making the hose have outstanding high pressure resistance. The cover is made from high quality synthetic rubber, making the hose resistant to abrasion, corrosion, weather, ozone, aging, sunlight and cut. Therefore, it has longer service life.

Hydraulic Rubber Hose SAE100 R1 Recommended For:

Medium pressure hydraulic hoses. Meets or exceeds the requirements of SAE 100 R1 Type AT and performance requirements of EN 853 1SN.

Hydraulic Rubber Hose SAE100 R1 Application Fields:

Mine hydraulic support, oilfield extraction machinery, mine/road/construction machinery.

INNER TUBE: oil resistant synthetic nitrile rubber

REINFORCEMENT: single layer of steel wire braided

COVER: Black, oil resistant, synthetic rubber

SURFACE: wrapped surface,smooth surface

Hydraulic Rubber Hose SAE100 R1 TEMPERATURE RANGE: -40ºC(-104ºF) to +100ºC (+212ºF)

Hydraulic Rubber Hose SAE100 R1 Standard: SAE 100 R1 AT

Main Features:

1/ No-skive design eliminates the need to remove the hose cover before 2/ 2/ crimping

3/ MSHA accepted cover

4/ 3000 PSI constant working pressure in all sizes

5/ It is made from the latest nanmeter material, providing good resistance to oil,ozone,and high pulse performance.

Product Features:

Premium Hose(Fc500/H471)

Easier Installation-46% improvement in force-to-bend, ½ SAE minimum bend in sizes -12 thru -24 and 33% reduction in bend radius for SAE 100R13-32

Environmentally Friendly - Class 0 Cool Down Leakage per SAE J1176 when assembled with the 4S/6S Fitting Series.

Reduced Downtime- using hoses that exceed industry performance requirements

Engineered Hose Assembly System-Quick and easy assembly through a matching and mating hose assembly process: Reduces the time to produce a hose assembly through color coordinated identifiers on the hose,hose fittings and crimp tooling

The specification of SAE 100 R1 steel wire reinforced hydraulic hose (1)

| Hose code | Size | Dash size | ID | WD | OD | |||||

| A | AT | |||||||||

| mm | inch | min | max | min | max | min | max | max | ||

| SAE100R1-01 | 5 | 3/16 | -3 | 4.6 | 5.4 | 8.9 | 10.1 | 11.9 | 13.5 | 12.5 |

| SAE100R1-02 | 6.3 | 1/4 | -4 | 6.2 | 7 | 10.6 | 11.7 | 15.1 | 16.7 | 14.1 |

| SAE100R1-03 | 8 | 5/16 | -5 | 7.7 | 8.5 | 12.1 | 13.3 | 16.7 | 18.3 | 15.7 |

| SAE100R1-04 | 10 | 3/8 | -6 | 9.3 | 10.1 | 14.5 | 15.7 | 19 | 20.6 | 18.1 |

| SAE100R1-05 | 12.5 | 1/2 | -8 | 12.3 | 13.5 | 17.5 | 19 | 22.2 | 23.8 | 21.5 |

| SAE100R1-06 | 16 | 5/8 | -10 | 15.5 | 16.7 | 20.6 | 22.2 | 25.4 | 27 | 24.7 |

| SAE100R1-07 | 19 | 3/4 | -12 | 18.6 | 19.8 | 24.6 | 26.2 | 29.4 | 31 | 28.6 |

| SAE100R1-08 | 25 | 1 | -16 | 25 | 26.4 | 32.5 | 34.1 | 36.9 | 39.3 | 36.6 |

| SAE100R1-09 | 31.5 | 1-1/4 | -20 | 31.4 | 33 | 39.3 | 41.7 | 44.4 | 47.6 | 44.8 |

| SAE100R1-10 | 38 | 1-1/2 | -24 | 37.7 | 39.3 | 45.6 | 48 | 50.8 | 54 | 52 |

| SAE100R1-11 | 51 | 2 | -32 | 50.4 | 52 | 58.7 | 61.9 | 65.1 | 68.3 | 65.9 |

The specification of SAE 100 R1 steel wire reinforced hydraulic hose (2)

| Hose code | Working pressure | Proof pressure | Min burst pressure | Min bending radius | Weight | |||

| MPa | psi | MPa | psi | MPa | psi | mm | kg/m | |

| SAE100R1-01 | 21 | 3045 | 42 | 6090 | 84 | 12810 | 90 | 0.2 |

| SAE100R1-02 | 19.2 | 2780 | 38.5 | 5580 | 77 | 11165 | 100 | 0.25 |

| SAE100R1-03 | 17.5 | 2540 | 35 | 5075 | 70 | 10150 | 115 | 0.31 |

| SAE100R1-04 | 15.7 | 2280 | 31.5 | 4570 | 63 | 9135 | 125 | 0.36 |

| SAE100R1-05 | 14 | 2030 | 28 | 4060 | 56 | 8120 | 180 | 0.45 |

| SAE100R1-06 | 10.5 | 1520 | 21 | 3045 | 42 | 6090 | 205 | 0.52 |

| SAE100R1-07 | 8.7 | 1260 | 17.5 | 2540 | 35 | 5075 | 240 | 0.65 |

| SAE100R1-08 | 7 | 1015 | 14 | 2030 | 28 | 4060 | 300 | 0.91 |

| SAE100R1-09 | 4.3 | 620 | 8.7 | 1260 | 17.5 | 2540 | 420 | 1.3 |

| SAE100R1-10 | 3.5 | 510 | 7 | 1015 | 14 | 2030 | 500 | 1.7 |

| SAE100R1-11 | 2.6 | 380 | 5.2 | 750 | 10.5 | 1520 | 630 | 2 |