Basic Info.

Model NO.

SKP-1525D

Glass Edging Machine Type

Glass Double Edging Machine

Grinding Head Number

20

Condition

New

After-sales Service

1 Year

Max Stencil Size

1900 * 3200 mm

Transport Package

Export Packing

Specification

CE, ISO, SGS

Trademark

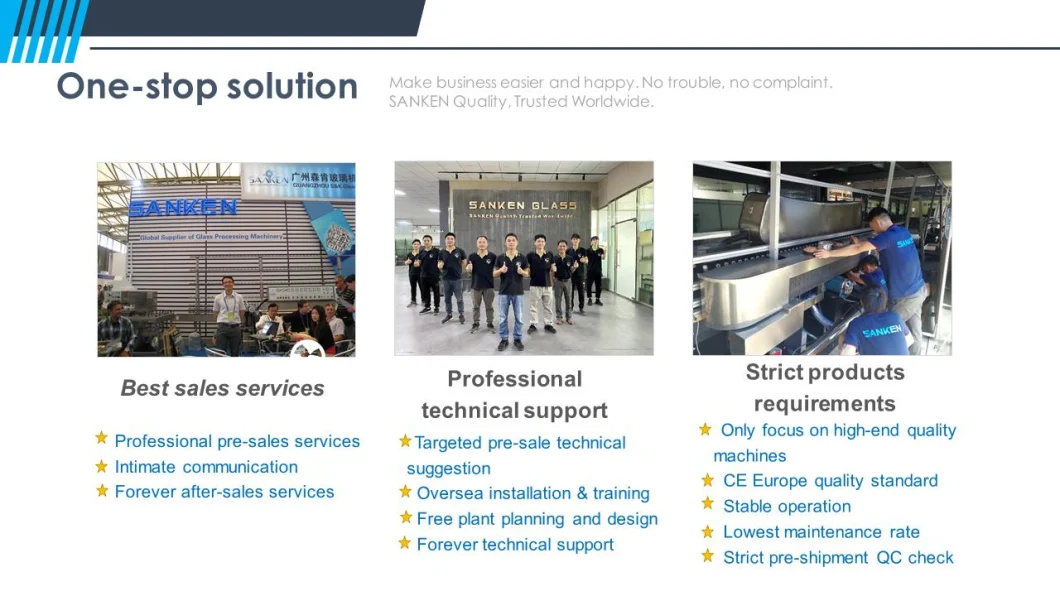

SANKEN

Origin

Guangzhou, Canton

Production Capacity

100000 PCS/Year

Product Description

SANKEN Vertical Screen Drying Oven is suitable for drying high - precision screen stencils

SANKEN Vertical Screen Drying Oven is suitable for drying

SANKEN Vertical Screen Drying Oven is suitable for drying

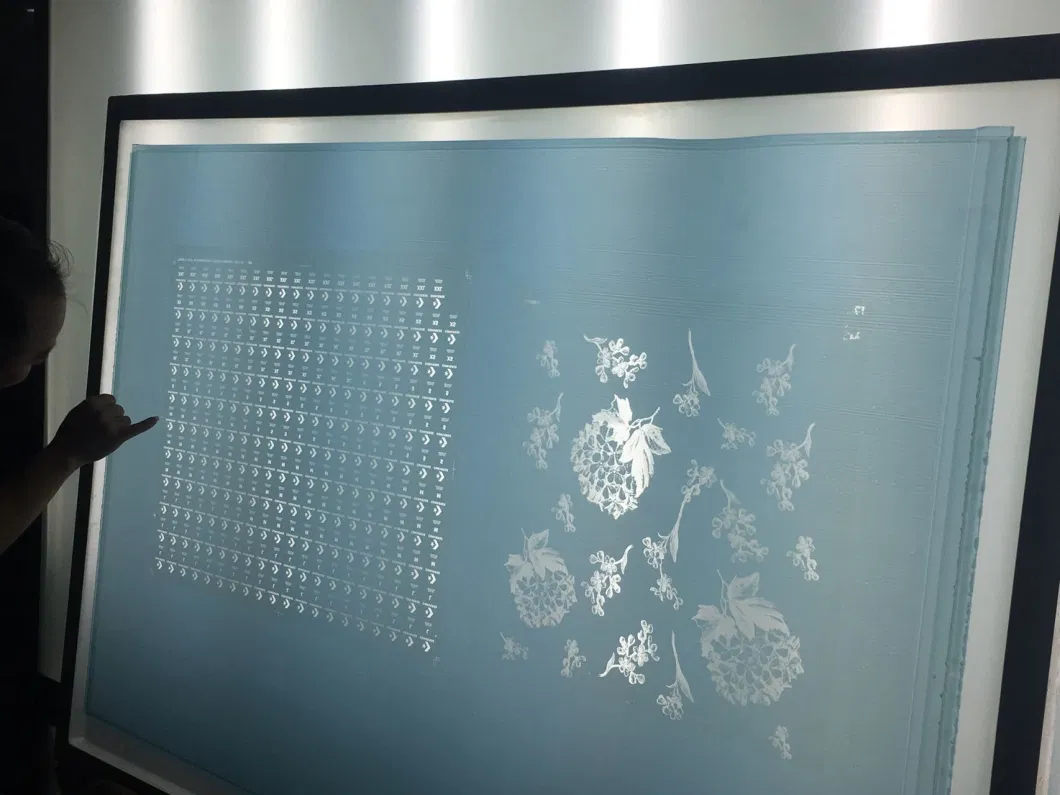

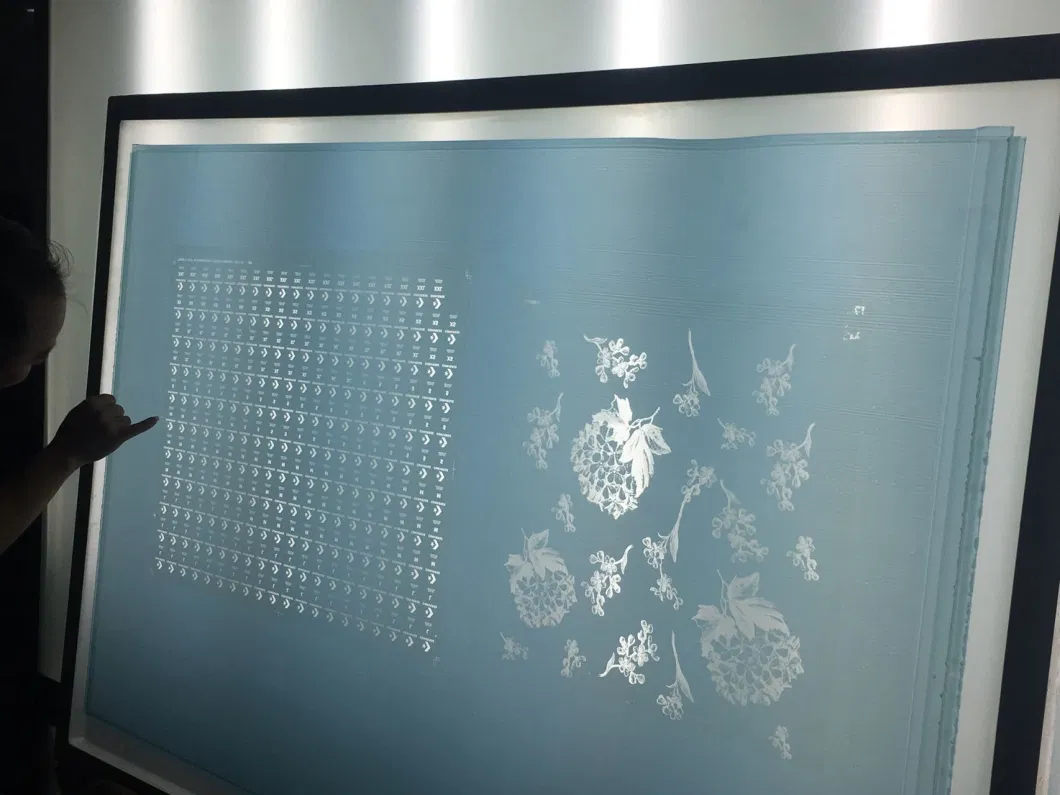

SANKEN Horizontal Screen Drying Oven is suitable for drying high - precision screen stencils , and is mainly used for screen drying after coating the sensitive emulsion .

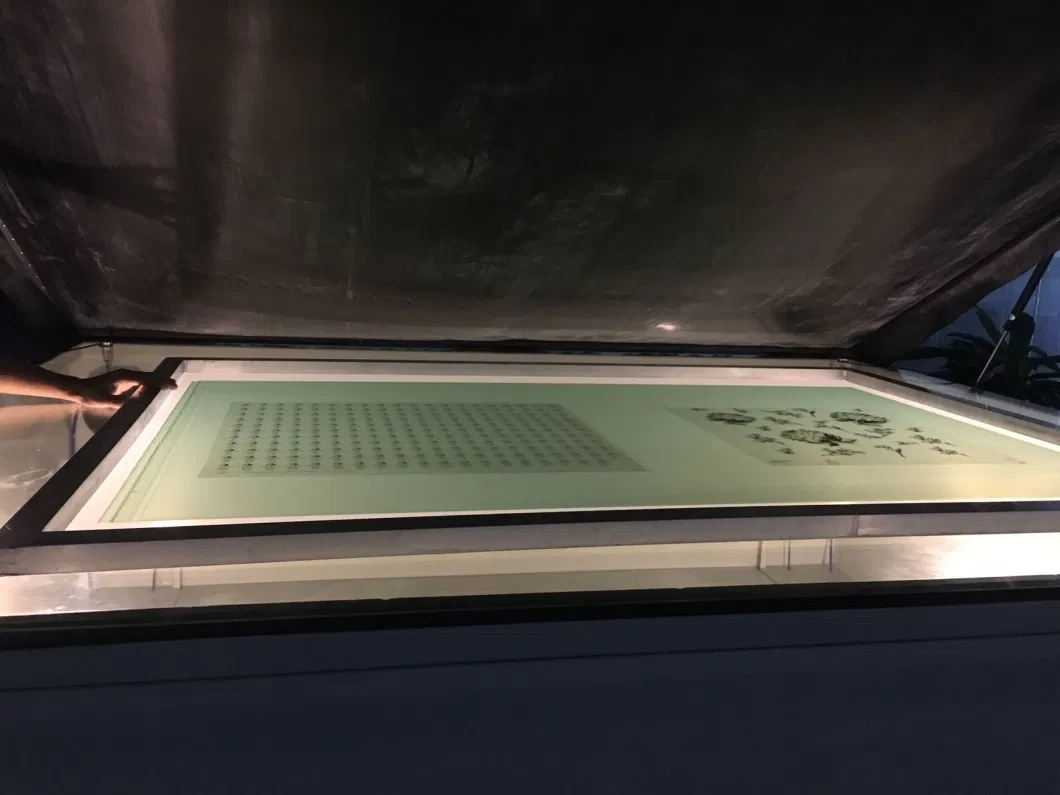

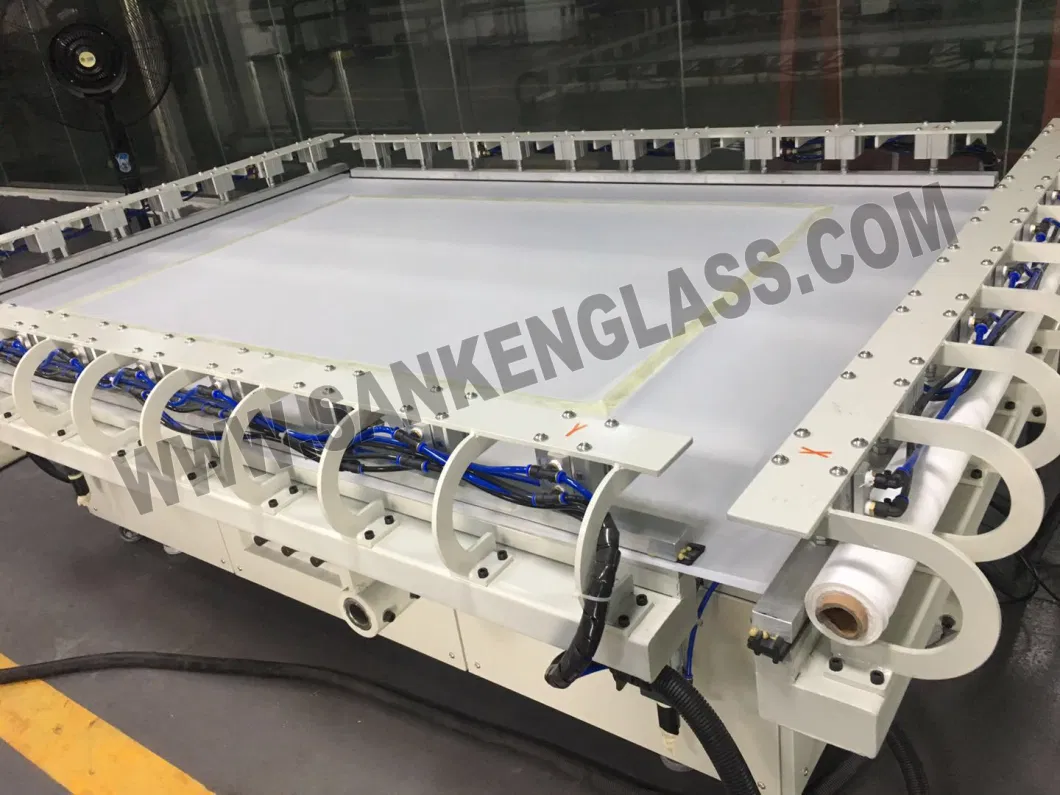

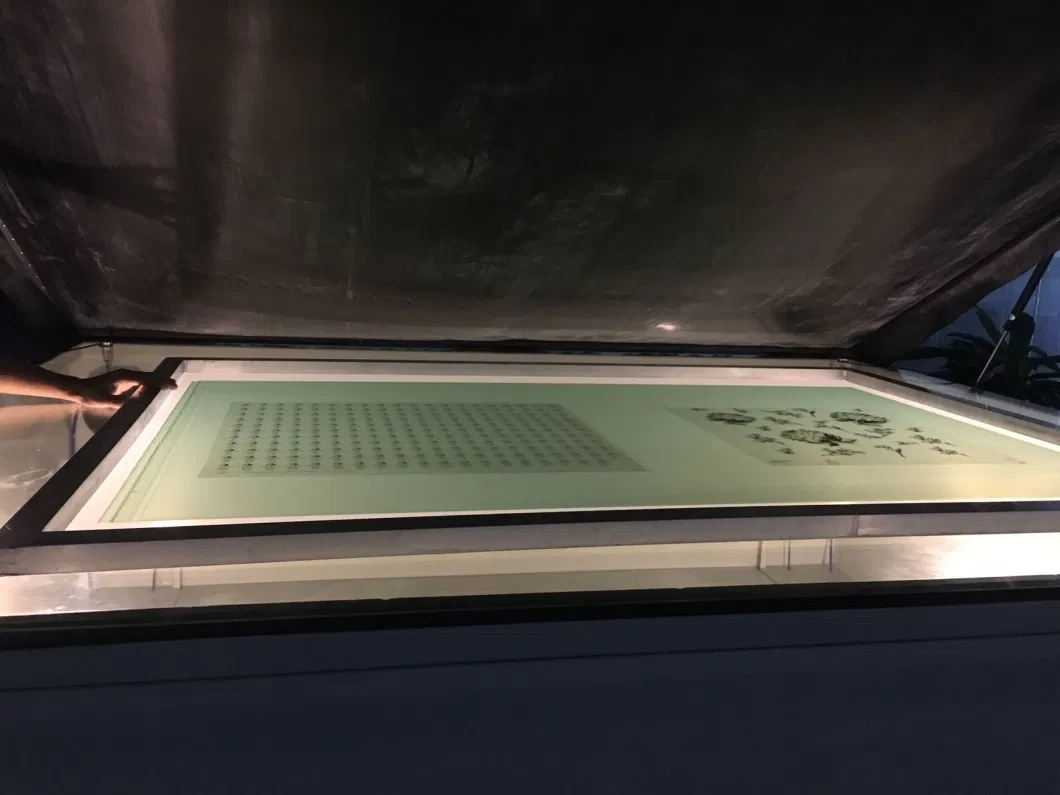

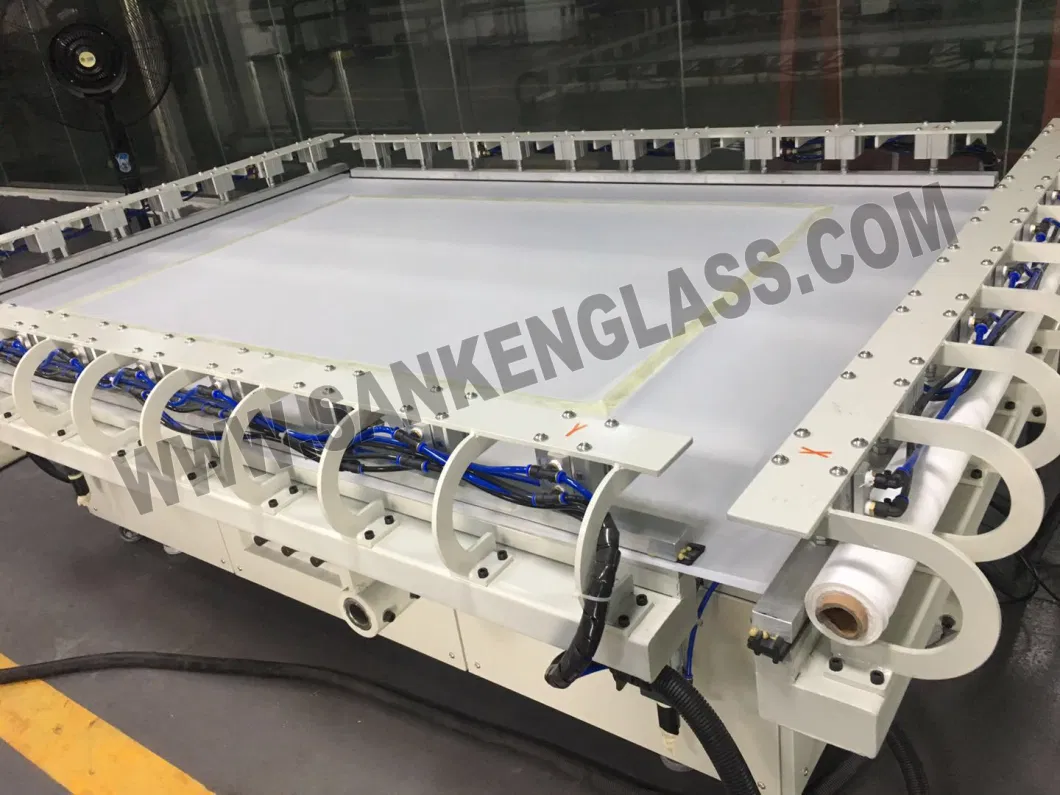

1. Horizontal drawer design , the screens are placed horizontally , and it is easy to pick and place .

2. Using track type bearing transmission , with good sealing performance .

3. It adopts high - quality temperature control components , with automatic constant temperature control .

4. It adopts stainless steel heaters , and the air is circulated through the centrifugal fan . The unique hot air circulation design makes the temperature rise rapidly and uniform , ensure the screen emulsion coating to dry uniformly .

5. Design for the screens printing surface is placed upwardly to ensure that the coating layer is smooth and will not damage .

SANKEN Vertical Screen Drying Oven is suitable for drying

SANKEN Vertical Screen Drying Oven is suitable for drying SANKEN Horizontal Screen Drying Oven is suitable for drying high - precision screen stencils , and is mainly used for screen drying after coating the sensitive emulsion .

1. Horizontal drawer design , the screens are placed horizontally , and it is easy to pick and place .

2. Using track type bearing transmission , with good sealing performance .

3. It adopts high - quality temperature control components , with automatic constant temperature control .

4. It adopts stainless steel heaters , and the air is circulated through the centrifugal fan . The unique hot air circulation design makes the temperature rise rapidly and uniform , ensure the screen emulsion coating to dry uniformly .

5. Design for the screens printing surface is placed upwardly to ensure that the coating layer is smooth and will not damage .

| Model | Max. size | Speed | Capacity | Power | Weight | Machine size |

| SKP-0812D | 1100 x 1700 mm | 15-20 min/cycle | 10 layer | 4 KW | 400 kgs | 1900 x 1300 x 1200 mm |

| SKP-1525D | 1900 x 3200 mm | 15-20 min/cycle | 10 layer | 6 KW | 1200 kgs | 3500 x 2200 x 1400 mm |

| SKP-2030D | 2500 x 3800 mm | 15-20 min/cycle | 10 layer | 12 KW | 1400 kgs | 4100 x 2800 x 1500 mm |

| SKP-2040D | 2500 x 4800 mm | 15-20 min/cycle | 10 layer | 12 KW | 1600 kgs | 5100 x 2800 x 1700 mm |