- Overview

- Product Description

- Product Parameters

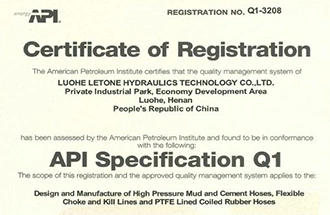

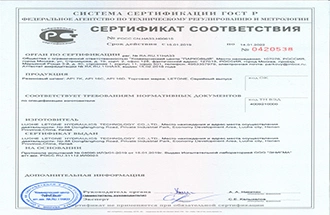

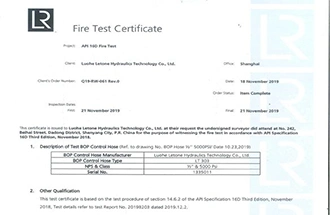

- Certifications

- Company Profile

- Packaging & Shipping

- Success Case

Basic Info.

Model NO.

LT586

Outerlayer

Skiving-Free Abrasion and Weather Resistant Synthe

Temperature Range

-40°c~ +121°c

Standard

Comply with ISO18752-DC Standard

Features

Low Bending Radius; High Pressure ;

Specification

10~100meters/roll

Trademark

LETONE

Origin

China

Production Capacity

50000000meters/Year

Product Description

SAE 100R9 Wire Spiral Hydraulic Rubber Hose

Application: Suitable for using oil base hydraulic oil, is suitable for the harsh conditions of high temperature and medium pressure hose

Yube: An inner tube of oil resistant synthetic rubber

Reinforcement:4 plies of steel wire Wrapped in alternating directions

Standard:Comply with ISO18752-DC standard

Features: Low bending radius; high pressure ; long service life ( weather resistant for more than 5 years and warrantied for 2 years with Letone specific hose connectors)

| TYPE | SIZE(inch) | I.D.(mm) | W.P.(MPa) | B.P.(MPa) | MIN.B.R.(mm) |

| SA599-4DC | 3/8" | 10.0 | 56 | 224 | 100 |

| SA599-4DC | 1/2" | 13.0 | 42 | 168 | 140 |

| SA599-4DC | 5/8" | 16.0 | 42 | 168 | 180 |

| SA599-4DC | 3/4" | 19.0 | 42 | 168 | 200 |

| SA599-4DC | 1" | 25.4 | 42 | 168 | 250 |

| SA599-4DC | 11/4" | 32.0 | 35 | 140 | 400 |

| SA599-4DC | 11/2" | 38.0 | 32 | 128 | 480 |

| SA599-4DC | 2" | 51.0 | 25 | 100 | 650 |

| SA599-6DC | 11/4" | 32.0 | 42 | 168 | 400 |

| SA599-6DC | 11/2" | 38.0 | 42 | 168 | 480 |

| SA599-6DC | 2" | 51.0 | 42 | 168 | 630 |

Established in 2003, Letone is an industry-recognized high-quality rubber hose manufacture and service company, which devotes to the production, R&D, and sale of rubber compounds, rubber hoses & fluid connectors and rubber-plastic seals. Thanks to its stable quality and good reputation in the market, Letone has won the"Top Ten Rubber Hose Enterprises in China" issued by the China Rubber Industry Association Rubber & Belt Branch for many consecutive years. On 15th Nov. 2021, Letone (Stock Code: 832225) is listed on the Beijing Stock Exchange.

Letone now has 46 high-speed steel wire braiders, 12 steel wire spiral production lines, 8 industrial hose production lines, 200 CNC lathes and 2 automatic rubber compound production lines service in-house. Meanwhile, Letone is capable to produce rubber compounds 15,000 tons per year, rubber seals and other rubber products 20 million pieces per year, and the annual production capacity of hydraulic hoses and industrial hoses has increased to 30 million meters.

FAQ | What materials are commonly used for chemical pipelines

Products used in the rigorous oil and gas industry must be resilient and of high quality to properly support these complex operations. Hoses and connections must be safe, versatile and efficient. Rubber hoses have their limitations when used in harsh environments. One of the problems is bubbling of the inner tube. Foaming is caused by fluid seeping into the rubber core tube over time. When the pressure is released quickly, the fluid will try to escape quickly and damage the rubber core tube, causing blisters, which in turn cause leak paths in the core tube. Letone Hydraulics has developed high pressure hoses specifically for subsea applications. The core tube is made of nylon, time- and field-proven for use in subsea applications, and chemically compatible with subsea control fluids.

Products used in the rigorous oil and gas industry must be resilient and of high quality to properly support these complex operations. Hoses and connections must be safe, versatile and efficient. Rubber hoses have their limitations when used in harsh environments. One of the problems is bubbling of the inner tube. Foaming is caused by fluid seeping into the rubber core tube over time. When the pressure is released quickly, the fluid will try to escape quickly and damage the rubber core tube, causing blisters, which in turn cause leak paths in the core tube. Letone Hydraulics has developed high pressure hoses specifically for subsea applications. The core tube is made of nylon, time- and field-proven for use in subsea applications, and chemically compatible with subsea control fluids.

Frequently Asked Questions | How high is the high temperature resistant hose

Slurry hoses are bulk delivery hoses for the offshore oil and gas industry. For transfer from shore to ship and onboard installation of drilling fluids, including most fluids used in hydrocarbon drilling operations. Especially those containing large amounts of suspended solids, emulsified water or oil and all types of water-based, oil-based and synthetic-based drilling fluids. Drilling, completion and workover fluids sometimes referred to as muds, although essentially free of solids, are not strictly believed to be successfully used with this hose.